No products in the cart.

Welcome to Pishro Energy Almas website.

Welcome to Pishro Energy Almas website.

Coiled Tubing Services

Pishro Energy Almas Kish offers comprehensive Coiled Tubing (CT) Services tailored to meet the complex requirements of modern well intervention, stimulation, and completion support operations. Utilizing high-performance equipment and field-proven procedures, we deliver reliable, safe, and cost-effective solutions across onshore assets.

Equipment Overview

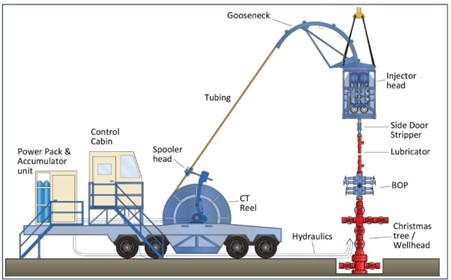

Our Coiled Tubing units are trailer-mounted, offering high mobility, rapid rig-up/down, and operational flexibility. The equipment is sourced from industry-leading manufacturers to ensure quality and durability.

Main Equipment Includes:

Trailer-Mounted Coiled Tubing Unit (Main + Auxiliary Trailers)

Coiled tubing is a continuous, flexible steel pipe wound on a large spool and used in oil and gas well operations for various intervention, stimulation, and completion tasks without the need to remove the production tubing. It allows for efficient downhole work such as acidizing, cleanouts, nitrogen lifting, mechanical milling, and tool deployment—all while the well remains live or under pressure. Known for its speed, versatility, and cost-effectiveness, coiled tubing has become a key technology in extending well life and optimizing production with minimal disruption.

Injector Head:

Pulling capacity: 80,000 lbs (80K)

Hydraulic dual-gripper chain drive system

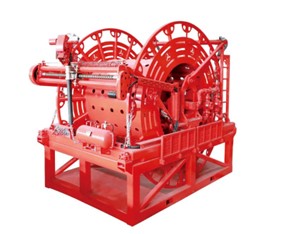

Reel

Reel Capacity:

Minimum 17,000 ft of 1.5″ Coiled Tubing string

Reel driven by hydraulic motor with precision braking system

Control Cabin:

Equipped with real-time monitoring systems (pressure, depth, speed, weight)

Air-conditioned, ergonomically designed for long operations

Power Pack:

Diesel engine-driven with hydraulic power transmission

Pressure Control Equipment (PCE):

Stripper packers, lubricators, BOPs

Rated up to 10,000 psi

Grease injection and hydraulic control units

Service Capabilities

Our Coiled Tubing systems support a wide range of intervention, stimulation, and mechanical operations including but not limited to:

Mechanical Services:

Fluid & Stimulation Services:

Other Specialized Services:

Pressure Control & Safety Systems

All operations are conducted with strict adherence to HSE and well control standards, using certified PCE:

Data Acquisition & Real-Time Monitoring

Our systems include advanced DAQ units for real-time job monitoring and post-job analysis:

Parameters recorded:

Optional Add-ons:

Operational Benefits with Us:

✅ Mobility: Rapid deployment and rig-up time

✅ Reliability: High-quality equipment from NOV and Chinese tier-1 brands

✅ Versatility: Suitable for a wide range of well types and job scopes

✅ Local Experience: Experienced personnel with knowledge of Iranian oilfields

✅ Compliance: Fully HSE-compliant and aligned with API/ISO standards

We operate across onshore and transitional zones in Iran and are capable of deploying to remote locations with full technical and logistics support.